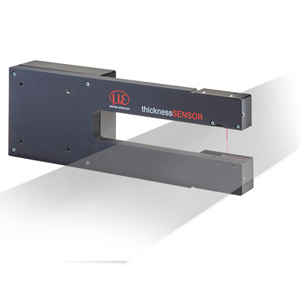

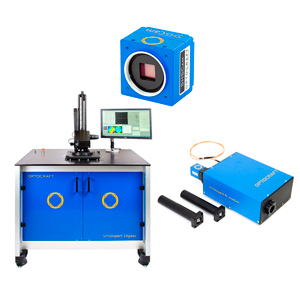

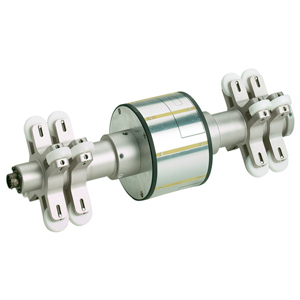

Parameter monitoring of continuous loop strap for cable ties

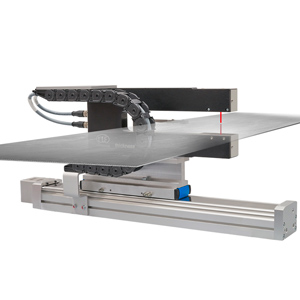

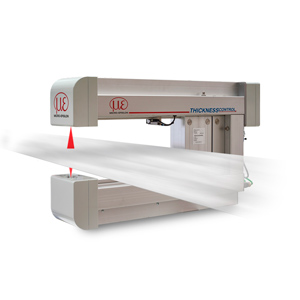

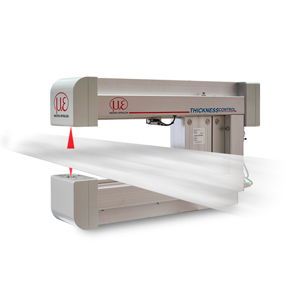

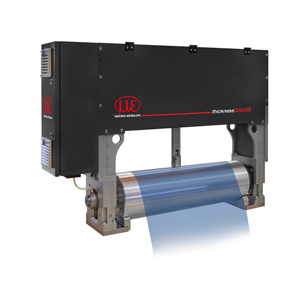

It is essential that the “width” and “height” of the cable tie strap, as well as the “tooth pitch” are monitored concurrently and constantly during the production of the continuous loop straps. These values are crucial to ensure a consistently good and reliable binding result.

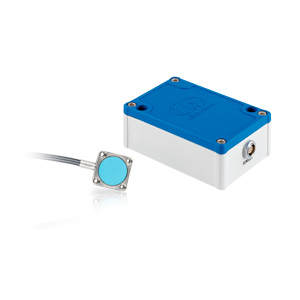

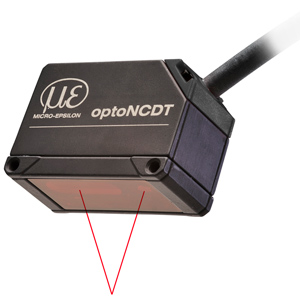

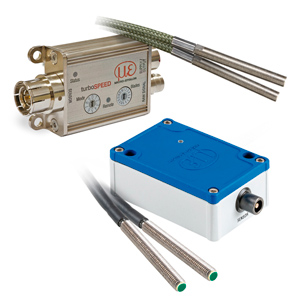

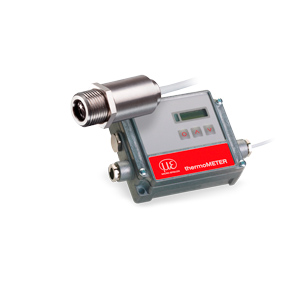

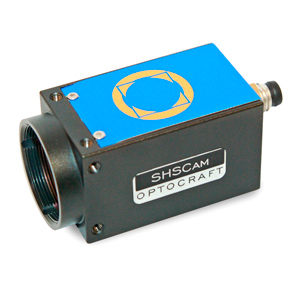

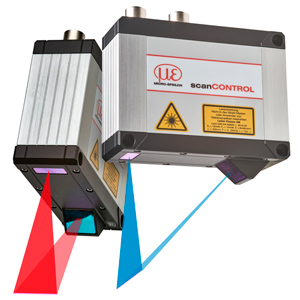

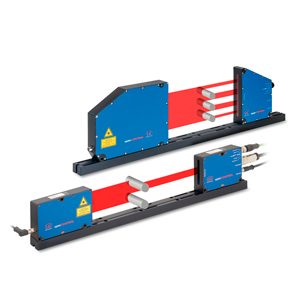

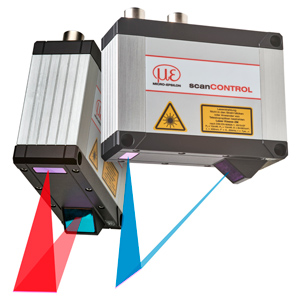

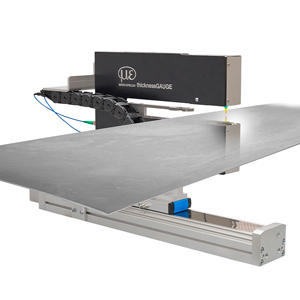

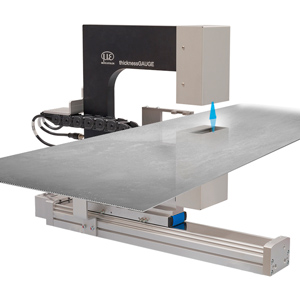

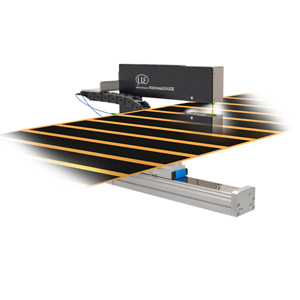

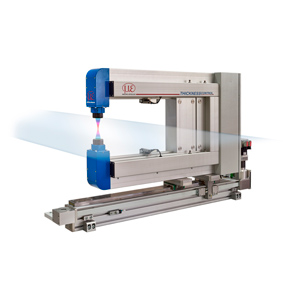

Monitoring of specific product parameters during the entire process is pivotal in ensuring the quality and uniformity of production. HellermannTyton GmbH therefore relies on a solution from ISW GmbH that uses a Micro Epsilon sensor system to monitor the parameters. The solution consists of a sensor combination that includes two optical precision micrometers and a triangulation sensor that is attached behind the extruder. Two ODC 2520-46 type sensors are positioned both horizontally and vertically and measure the height and width of the strap.