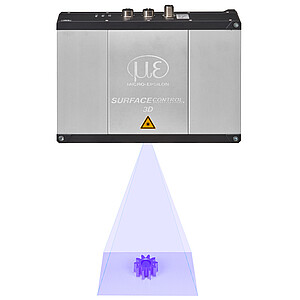

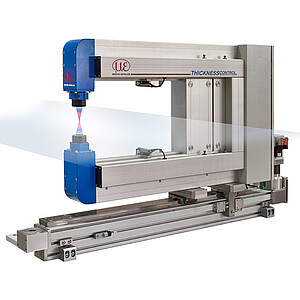

Measurement of the sprayed skin thickness

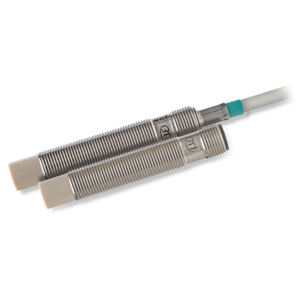

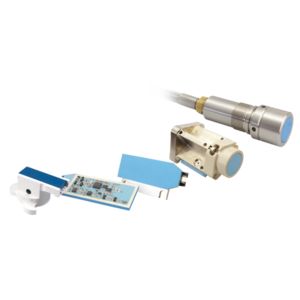

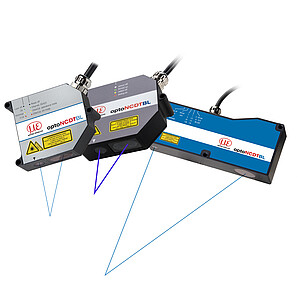

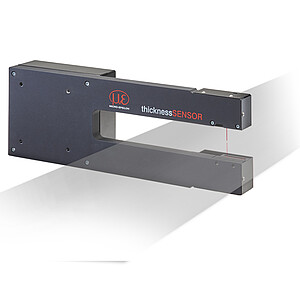

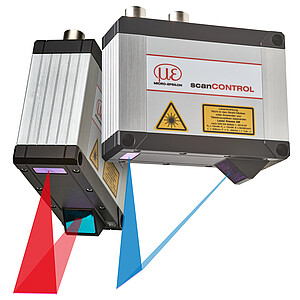

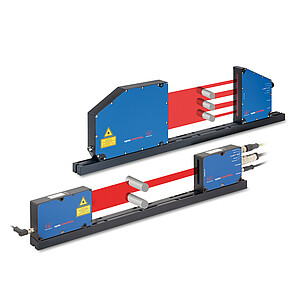

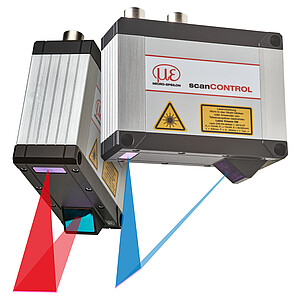

Sprayed skins for vehicle dashboards and for airbag cladding are sprayed into a heated mold using a robot-guided nozzle. For safety reasons, extremely low tolerances are required for airbags. For this reason, the thickness of the sprayed skin must be inspected inline during the spraying process. The measurement is performed using a combination sensor (an eddy current displacement sensor and a laser displacement sensor) which is attached to the robot arm. The eddy current sensor measures the distance to the nickel-coated spray mold and has an opening in the center through which the laser sensor measures the distance to the sprayed skin. When subtracted, both signals provide the thickness of the sprayed skin.